Views: 7 Author: Site Editor Publish Time: 2022-12-08 Origin: Site

Bearings use a relatively simple structure: balls with inner and outer smooth metal surfaces to help roll. The ball itself carries the weight of the load - the force of the weight of the load is what drives the rotation of the bearing.

However, not all loads force the bearing in the same way. There are two different loads: radial and thrust.A radial load, as in a pulley, simply puts weight on the bearing, causing the bearing to roll or rotate due to tension. Thrust loads are significantly different and stress the bearings in a completely different way.

If a bearing (think tire) flips over on its side (now think tire swing) and is subjected to full force at that angle (think three kids sitting on the tire swing), this is called a thrust load. Bearings used to support bar stools are examples of bearings that take thrust loads only.Many bearings are susceptible to radial and axial loads. For example, car tires are subjected to radial loads when traveling in a straight line: the tires roll forward in a rotational manner due to tension and the weight they support.

Bearing classification:

1. Ball bearings

Ball bearings are very common because they can accommodate radial and axial loads, but only a small amount of weight. They exist in a variety of applications, such as roller blades and even hard drives, but are prone to deformation if they are overloaded.

2. Roller bearings

Roller bearings are designed to carry heavy loads - the main rollers are cylindrical, which means that the load is distributed over a larger area, enabling the bearing to carry more weight. However, this construction means that the bearing can accommodate mainly radial loads, but is not suitable for thrust loads.

For applications where space is an issue, needle roller bearings can be used. Needle bearings are suitable for small diameter cylinders and are therefore easier to fit in smaller applications.

3. Ball thrust bearing

These types of bearings are designed to handle thrust loads almost exclusively in low-speed, low-weight applications. For example, bar stools utilize ball thrust bearings to support the seat.

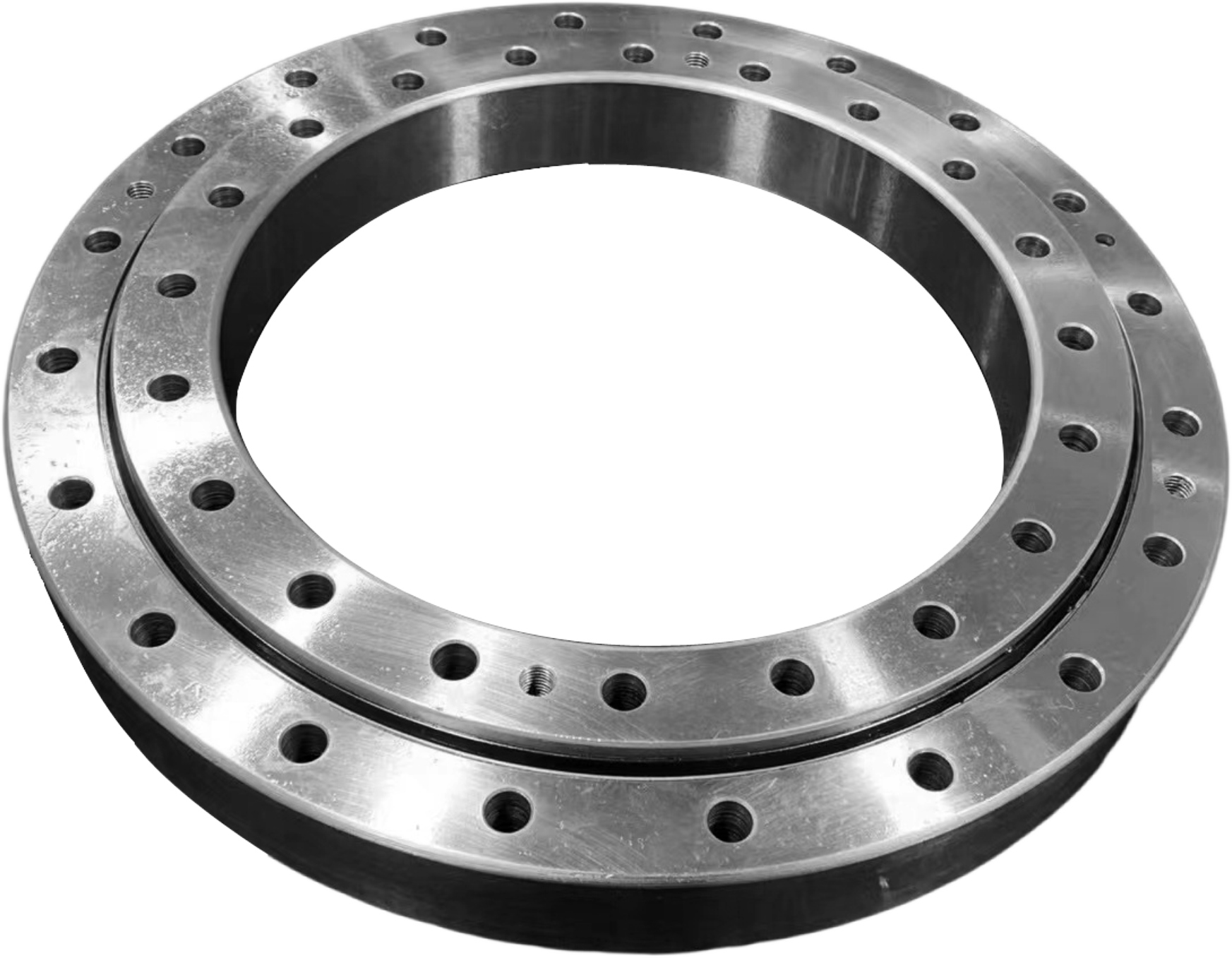

4. Roller thrust bearing

Roller thrust bearings are much like ball thrust bearings in that they accommodate thrust loads. The difference, however, is the amount of weight the bearing can support:

Roller thrust bearings can support sign

5. Tapered roller bearings

This type of bearing is designed to handle large radial and axial loads - due to their load versatility, they are found in automotive wheel hubs, as wheels are expected to withstand extreme radial and thrust loads.